The main benefits of a Becker Bulb Rudder are:

- No rudder-induced hub cavitation

- Reduced rotational losses in the slipstream

- Reduced hub vortex losses

- Reduced vibration and noise

Better performance with bulb rudders

Ship rudders are generally situated in complex, highly turbulent flow fields. This offers opportunities for significant power savings by recovering some of the associated flow energy losses through careful design of the propulsion and steering system. The Becker rudder bulb provides such an optimised solution.

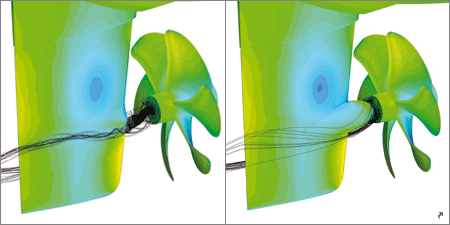

Water flow around a rudder without (left) and with (right) a Becker Rudder Bulb

The rudder bulb system consists of a streamlined bulb fixed at the leading edge of the full spade rudder, which is situated aft of the propeller hub. The transition between bulb and propeller hub is bridged by a fairing cap.

The integrated rudder bulb minimises energy losses behind the propeller hub by eliminating flow separation and very effectively reducing wasteful fluid turbulence. In addition, careful design of both the bulb geometry and twisted rudder leading edge ensures optimal energy recovery from the propeller slipstream.

The propeller hub fairing is designed to guide the flow smoothly over the bulb. Thus, the hub fairing and bulb are developed as a single hydrodynamic entity from the outset. The resulting shape and dimensions are dependent on the particulars of the propeller and hull and can therefore vary from case to case.

This rudder bulb system can be applied to virtually every situation, making it suitable for both new-build and retrofit projects alike.

Proven performance during model tests

Our research and development department is able to simulate the performance behaviour of the whole vessel prior to model tests or sea trials. Computational Fluid Dynamic (CFD) simulations of propeller/rudder setups with customised rudder bulb and twisted leading edge design have shown a reduction in power requirements of approx. 4% when compared to conventional rudder designs.

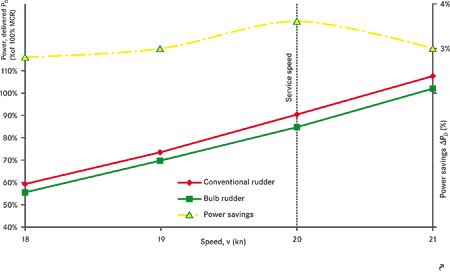

Test results of reduced power requirements for a twin screw car ferry

Comparative model tests of bulb rudders and conventional full and half spade rudders at different towing tank facilities have revealed propulsion efficiency improvements for different vessel types. For example:

- Approx. 3% energy savings for a 2,500 TEU container ship at 19 kn

- Approx 4% energy savings for a 195 m long RoRo ferry at 20 kn

- Approx. 3% energy savings for a 60k LNG carrier at 18 kn

- 6-7% energy savings for a 220 m RoPax ferry at 25 kn

Further tests in the cavitation tunnel have demonstrated the elimination of harmful hub vortex cavitation following installation of a rudder bulb. This makes the overall rudder system a more reliable solution.

Conclusion: A 2-4% reduction of fuel requirements

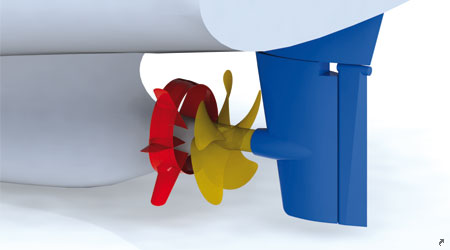

Becker Twisted Fin® and bulb rudder arrangement

|