|

About KSR (King Support Rudder).

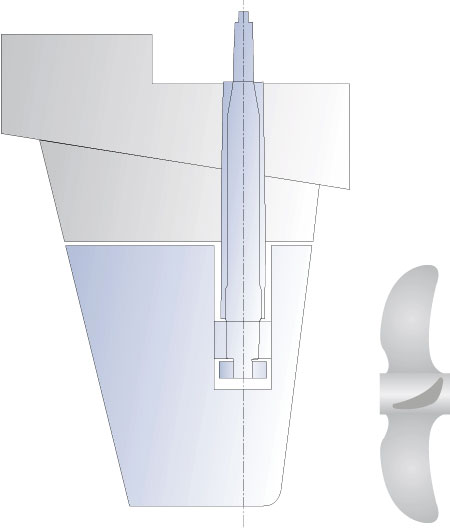

The KSR (King Support Rudder) design extends the trunk into the rudder blade and makes it possible for Becker’s full spade rudders, such as the TLKSR® Twisted Leading Edge Rudder, the FKSR Flap Rudder or the Schilling® KSR with unchallenged manoeuvrability to be supplied for vessels of any type and size. With the KSR design Becker can supply full spade rudders of practically any size.

Becker rudder profiles for the KSR design:

- Becker Twisted Leading Edge Flap (TLFKSR)

- Becker Twisted Leading Edge (TLKSR®)

- Becker Flap (FKSR)

- Schilling® KSR

- NACA (KSR)

In order to avoid typical disadvantages of conventional rudders, Becker Marine Systems has developed the KSR (King Support Rudder) bearing arrangement concept. With this arrangement the trunk is extended into the rudder blade so that the lower neck bearing is positioned as close as possible to the vertical centre of pressure on the rudder. This results in reduced stresses and bending moments in the rudder blade as well as in the rudder stock.

The reaction forces in the neck and carrier bearings are much smaller, making it a very rigid rudder and with a consequently high natural frequency above the exciting frequency of the propeller, making the risk of the resonance very unlikely. Vibrations are reduced to a minimum.

TOP

|