- Becker Twisted Fin® – Introduction

- Becker Twisted Fin® – Development

- Becker Twisted Fin® – Case Study

Introduction.

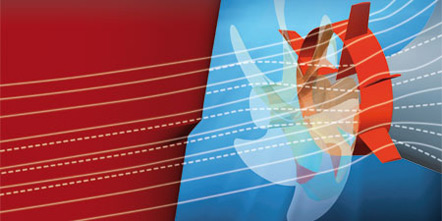

Becker Marine Systems has reacted to the heavy demand of shipping companies for an energy-saving device for faster vessels. After two years of research and based on three years operational experience with the Becker Mewis Duct® a new energy-saving device for container ships and other types of fast vessels with bulbous stern is entering the market – the Becker Twisted Fin®.

- Fuel savings of up to 3%

- Reduction of NOx and CO2 emissions

- Return on investment in 6-15 months

- Structural guarantee of many years

- Guarantee of power reduction as verified by model test:

“Money saved or money back”

- Suitable for newbuildings and retrofits

- No moving parts, no maintenance required

- Fast installation

TOP

|